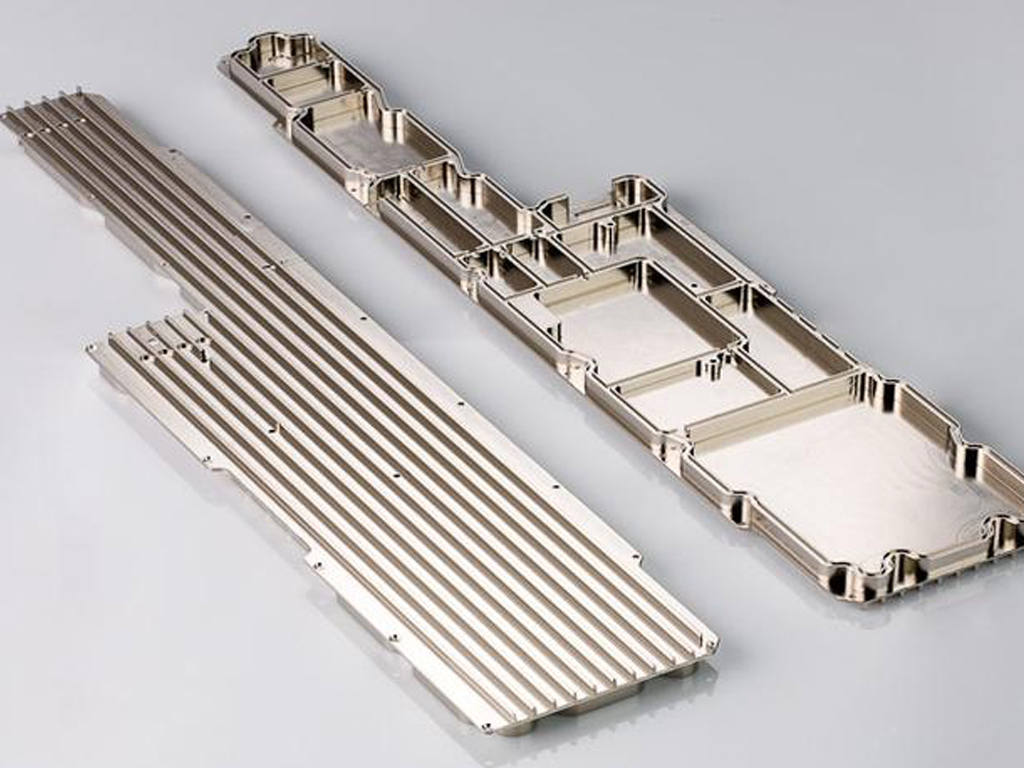

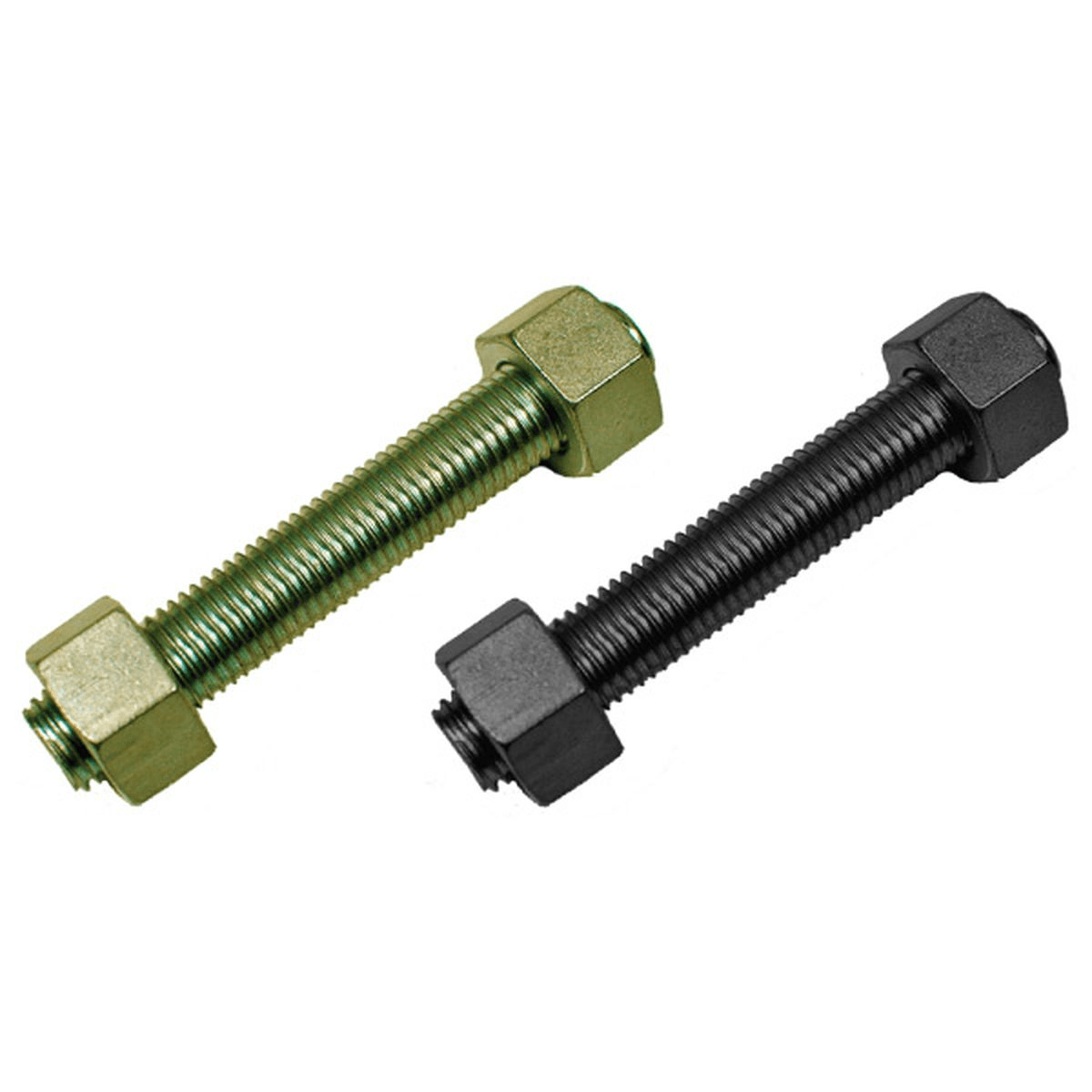

Simone offers various finish options for your products. We do the chromate conversion coating, electroless nickel, passivation, zinc plating, anodizing, and so on to protect the products’ surface. We also provide the options for sandblasting, brushing, and laser etching to alter the products’ surface conditions.

Tech details

We can fine-tune the parameters of the above finish process to meet your targets, such as various ASTM finish specs or different corrosion resistance with the salt spray test data.

Below are the three most important concerns for the finished products.

Cosmetic quality

Flaking, blistering, contaminations are common issues for the finish process. We offer various solutions to these problems for all kinds of substrates.

Corrosion resistance

Depending on your need, we can achieve 8 to 12 hrs salt spray test with the standard process. If you need higher corrosion resistance, we offer sealing process and thicker coating to get longer than 96 to 120 hrs salt spray test.

Wear resistance

We can tailor the parameters of the finish process, such as thickness or heat treatment, to meet the required hardness or wear resistance within a feasible budget.