Sheet metal fabrication is a manufacturing genre including stamping, laser cutting, and sheet bending and folding. We can turn the sheet metals into your functional products.

Tech details

Stamping

Stamping is the process of placing the sheet in the die and press it to bend/fold the sheet metal along the features of the die.

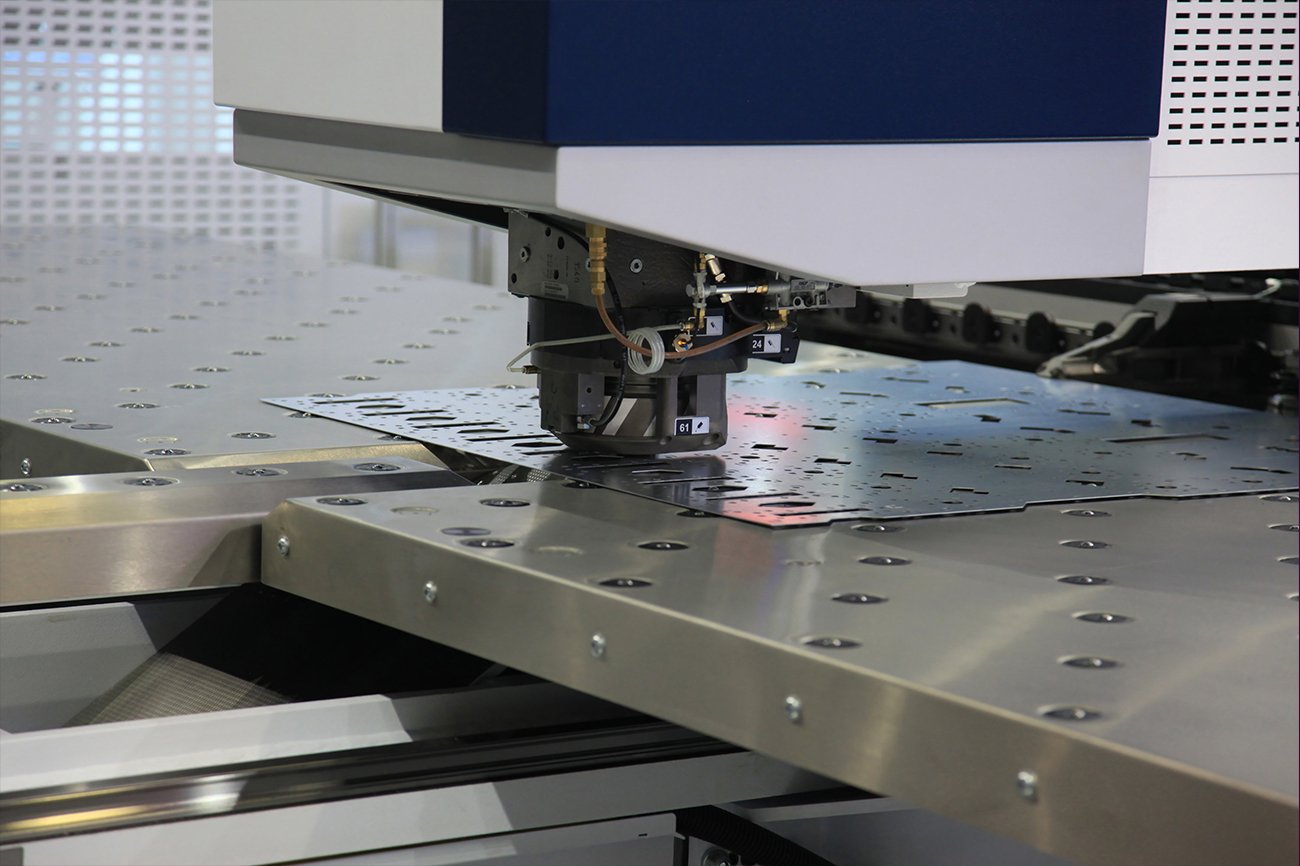

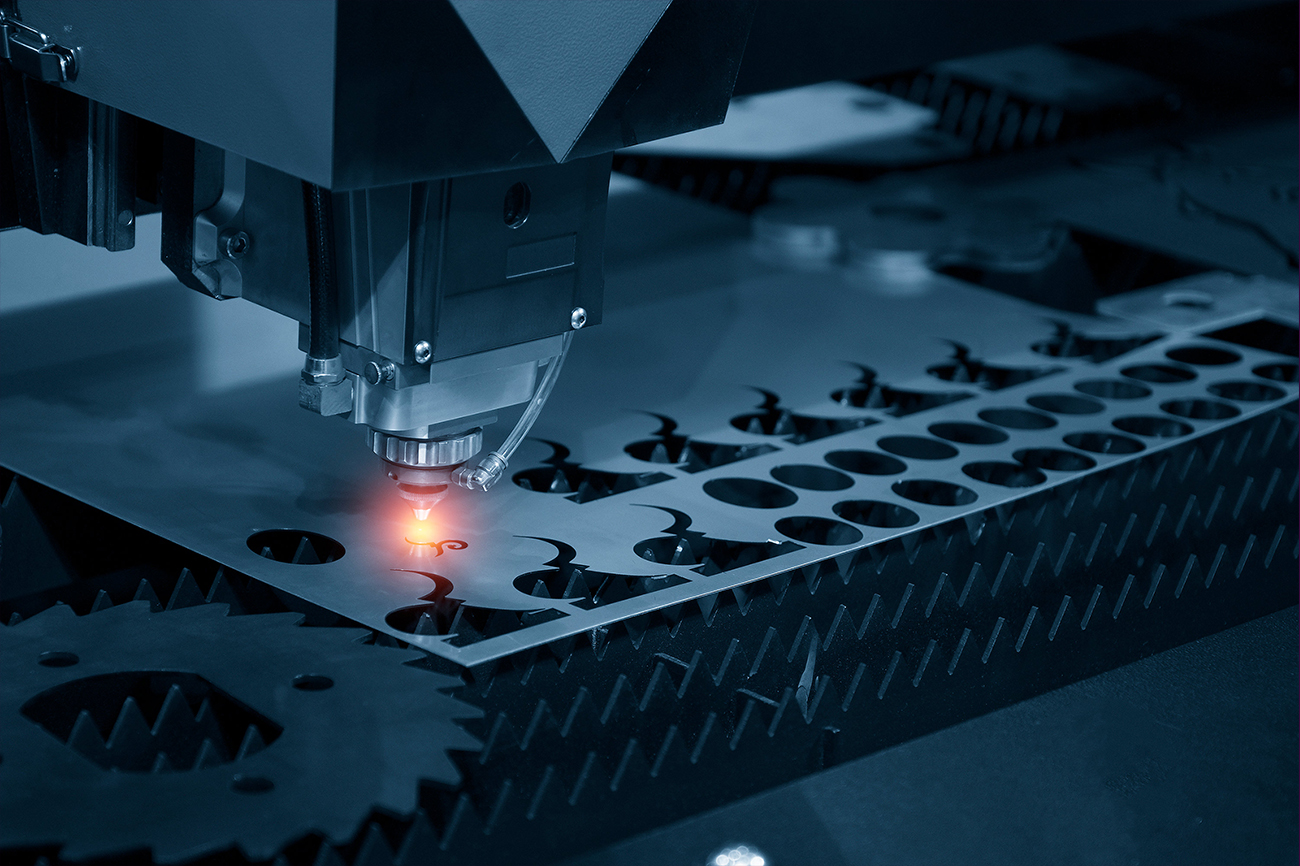

Laser cutting

Laser cutting is one of the most precise cutting tools. It requires experience to get a good cutting line by adjusting the focal plane, laser intensity, and substrate reflectivity.

Bending and folding

It’s similar to stamping, yet there is no need for a die. We use a numerically controlled tool to bend or fold the sheet metal into the desired structure. This is the most economic and fast method to produce sheet metal products.

Applications

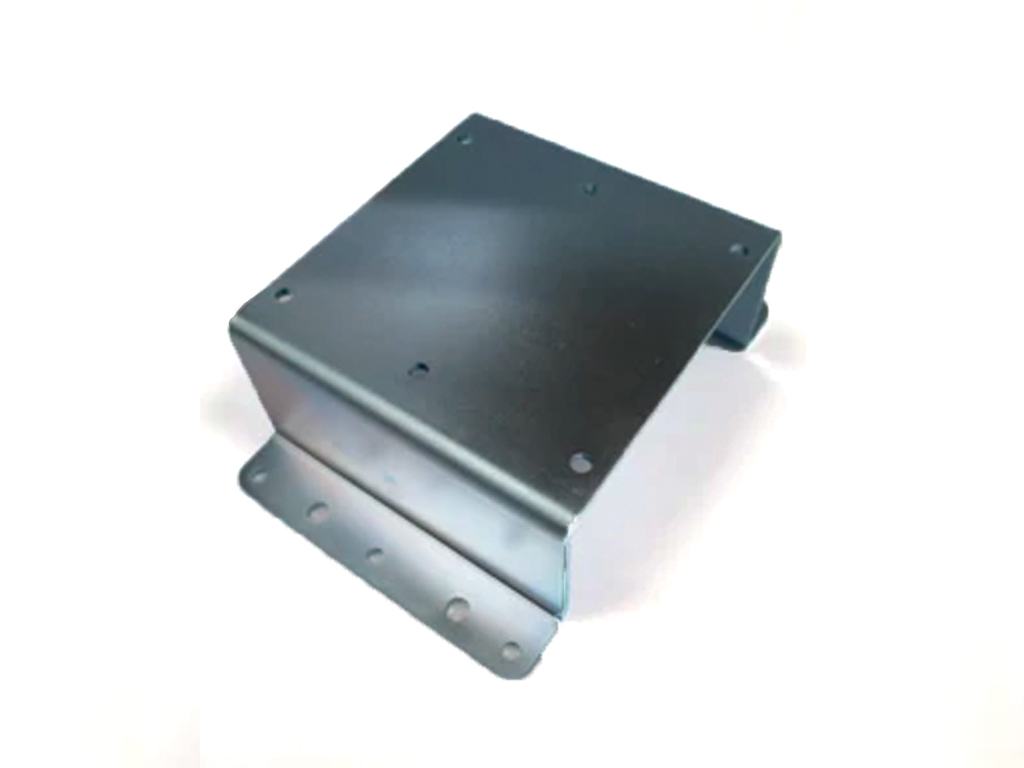

Small mechanical components

Most small mechanical components are price sensitive and require a much shorter lead time. The stamping process meets all these requirements.

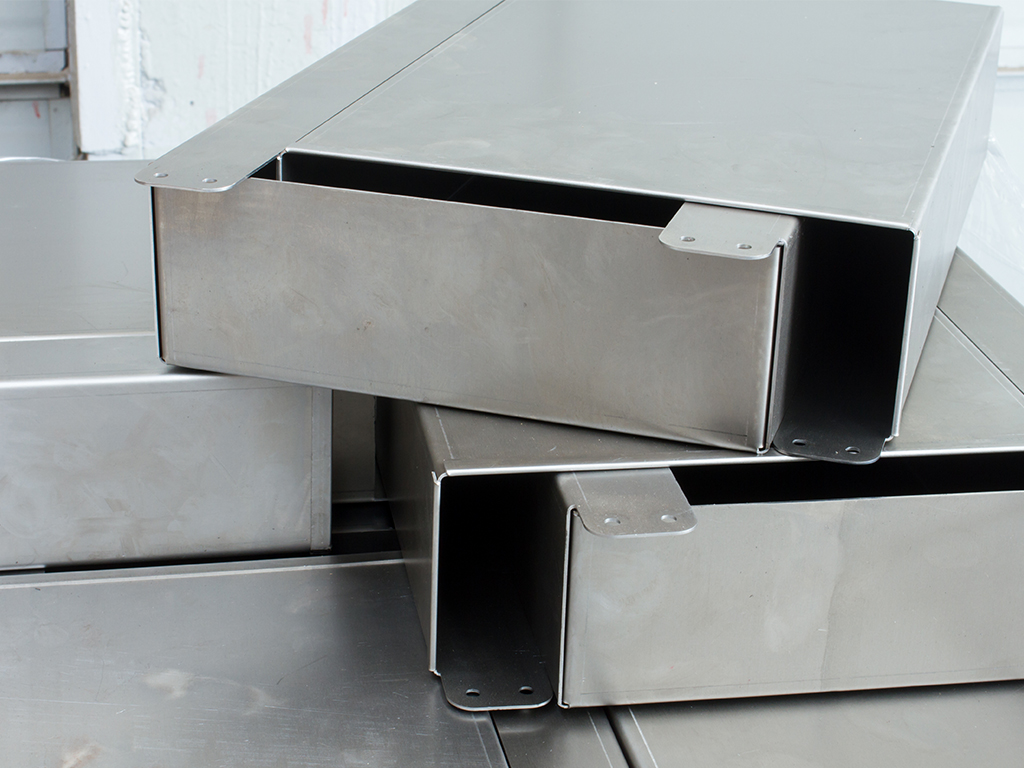

Housing for telecom products

Data centers require flexible housing solutions for their high-end processors. Simone can use sheet metal fabrication to manufacture high-quality yet low-cost housing parts.