Most plastic parts are price sensitive. Therefore, you will need the injection molding technique to reduce the cost. We can design and build the injection molds that suit your products within 1 week.

Tech details

Injection molding is a process that we feed the material into the heated barrel and inject it into the mold. After cool down, we can get out the product. The whole process heavily depends on the injection parameters and the mold design.

Applications

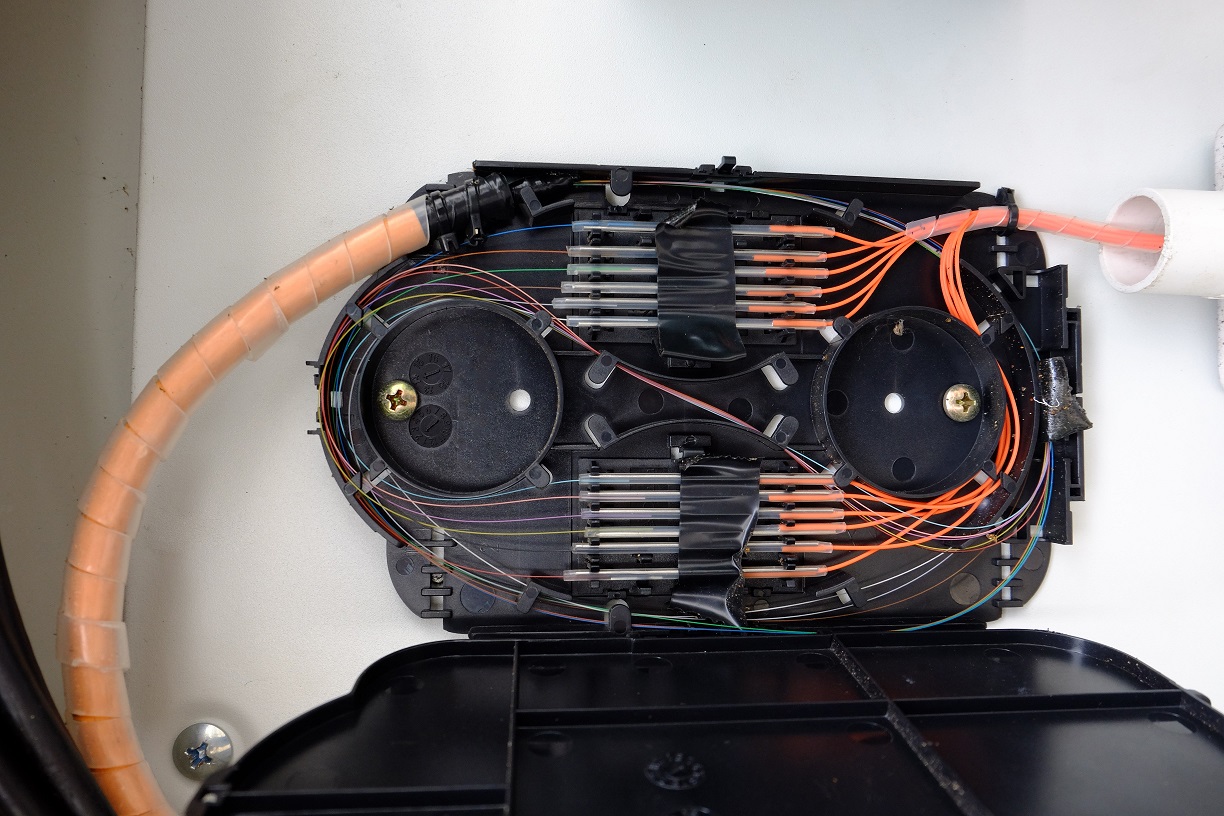

Fiber related plastic hardware

The fiber enclosure or tray requires high precision and sturdy structure, especially at the gaps. Otherwise, it’s difficult to hold the thin fiber where it should be.

Enclosure for outdoor consumer products

We have various plastic materials for all kinds of consumer products. We provide anti-UV, Rohs compliant, or fire-retardant plastics to meet your needs. These injection molded parts can survive in the most severe environment.